E-Bike Motor Stuttering After Overheating? Diagnosing and Fixing Thermal Gremlins

Heat is an inevitable byproduct of any hardworking motor, but excessive heat can push components beyond their operational limits, leading to the performance issues you're noticing. This in-depth guide will illuminate the common culprits behind this heat-induced stuttering and provide an step-by-step approach to troubleshoot, fix, and prevent it from derailing future rides.

Why Overheating Leads to Motor Stutter

E-bike motors, especially when pushed hard during long climbs, high-speed cruising, or carrying heavy loads, generate significant heat. While they are designed to dissipate a certain amount of this thermal energy, prolonged or extreme conditions can lead to overheating. When an e-bike motor overheats, various components can be temporarily or even permanently affected.

The "stuttering" itself usually manifests as a jerky, inconsistent, or pulsing power delivery. It might feel like the motor is trying to engage but can't maintain smooth output, or it might cut out intermittently. This isn't the motor just being tired; it's an indication of underlying issues triggered by excessive temperatures, ranging from sensor malfunctions to protective measures enacted by the e-bike's electronic brain, the controller.

SEE ALSO Why Your Electric Bike Motor Isn’t Working

Why Your E-Bike Motor Stutters Post-Overheating

Several factors can contribute to your e-bike motor stuttering after overheating. Identifying the specific cause can be a process of elimination, but understanding these possibilities is key.

Thermal Stress on Motor Windings and Hall Sensors

-

Motor Windings: The copper windings within your motor are coated with an insulating enamel. Excessive heat can degrade this insulation over time, leading to potential short circuits between windings (though this is a more severe failure). More commonly related to stuttering, the electrical resistance of copper increases with temperature, which can subtly alter motor performance and efficiency, contributing to further heat buildup.

-

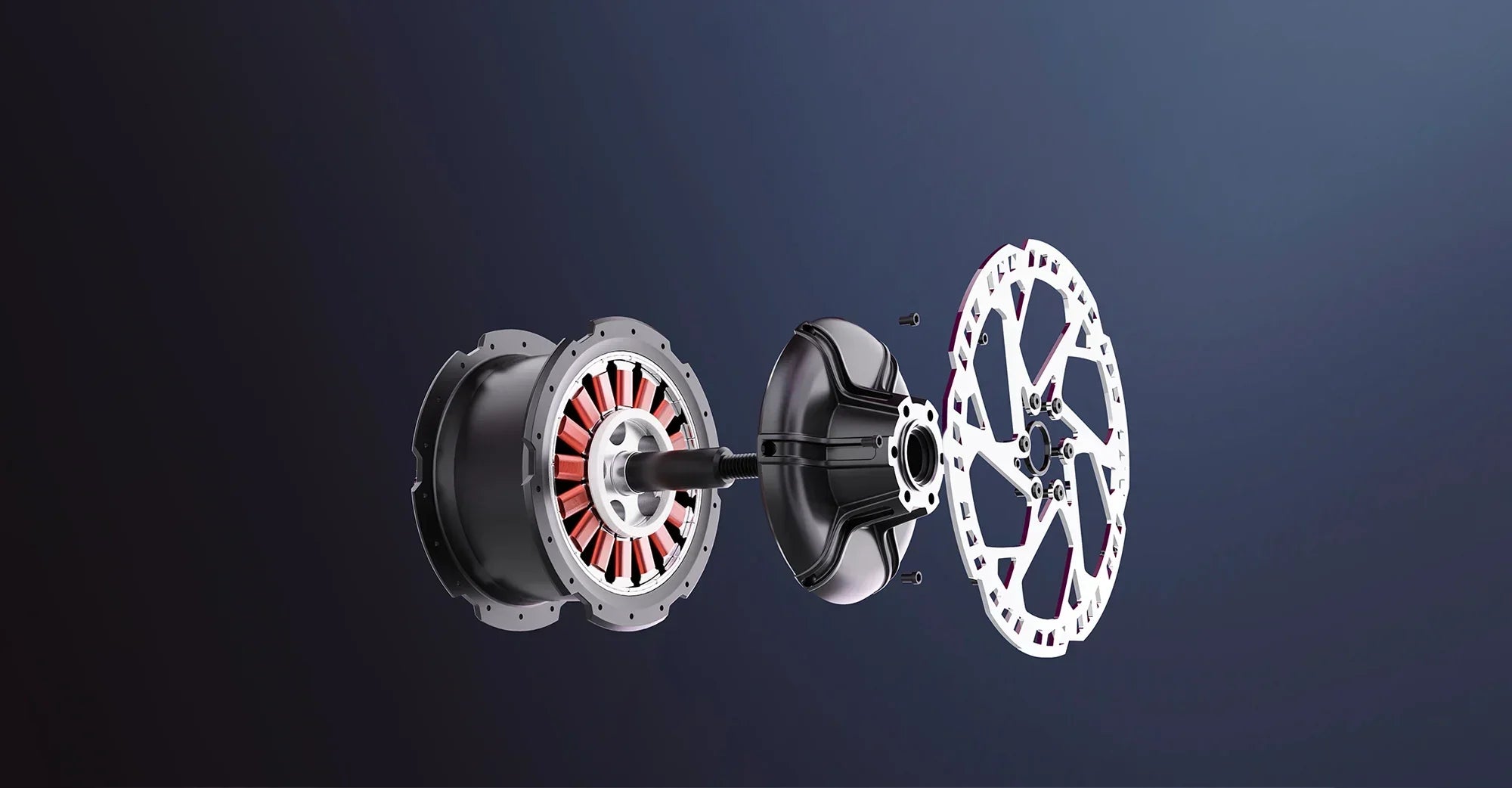

Hall Sensors: These critical sensors are embedded within the motor to detect the rotor's position, allowing the controller to energize the motor phases in the correct sequence for smooth rotation. Hall sensors are semiconductor devices and can be quite sensitive to high temperatures. When overheated, their signal can become erratic, intermittent, or fail altogether. If the controller receives faulty or missing Hall sensor signals, it cannot accurately time the power delivery to the motor phases, resulting in the classic symptoms of jerky e-bike motor operation or stuttering. This is one of the most common causes of heat-induced stuttering.

Damaged or Loose Phase Wires

The phase wires are the three thick wires that carry the electrical current from the controller to the motor coils.

-

Insulation Degradation: Intense heat, especially if sustained, can soften or damage the insulation on these phase wires.

-

Connector Issues: Heat can also cause the metal in connectors (both at the motor end and the controller end) to expand. Upon cooling, they might not return to their original tightness, leading to poor electrical contact. Vibration can exacerbate this. A loose or corroded connection acts like a bottleneck, causing irregular current flow, increased resistance (generating more heat at the connection point), and ultimately, motor stuttering as power delivery becomes inconsistent.

Controller Overload or Thermal Protection

The motor controller is the command center of your e-bike's power system. It manages the power flow from the battery to the motor.

-

Thermal Detection: Most controllers have their own internal temperature sensors or monitor the motor's temperature (via thermistors or by inferring from Hall sensor data or current draw).

-

Protective Measures: If the controller detects that it, or the motor, is overheating, it will often enter a protective mode to prevent permanent damage. This can manifest as a reduction in available power (limp mode) or by intermittently cutting power, which the rider perceives as stuttering or the e-bike motor cutting out. This is especially common during hard acceleration or sustained high load when the system is already hot.

Battery Voltage Sag Under Load

Overheating conditions often coincide with periods of high current draw (e.g., climbing a steep hill).

-

Voltage Drop: Under such heavy loads, the battery's voltage can temporarily drop, an effect known as "voltage sag." This is more pronounced in older batteries, batteries with a low state of charge, or those not rated for the high discharge currents being demanded. Heat further exacerbates voltage sag as it increases internal resistance within battery cells.

-

BMS Intervention: The Battery Management System (BMS) is designed to protect the battery cells from damage. If the voltage sags too low, the BMS might temporarily cut power to prevent cell damage. This sudden power cut, even if brief, will feel like a motor stutter or a complete, momentary shutdown.

Magnetic or Sensor Alignment Issues

While less common as a direct result of a single overheating event, repeated thermal stress and mechanical vibrations can, over time, contribute to subtle misalignments.

-

Sensor Position: If a Hall sensor or an external speed sensor becomes slightly misaligned relative to the magnets it's supposed to read, the signals sent to the controller can become inconsistent. Heat can cause materials to expand, potentially worsening a pre-existing slight misalignment.

-

Impact: This can lead to missed sensor readings, causing the controller to misinterpret the motor's speed or position, resulting in stuttering or inefficient operation.

Step-by-Step Fixes for a Stuttering E-Bike Motor

If your e-bike motor starts its stuttering act after getting hot, here's a systematic approach to diagnose and address the issue. Safety first: Always ensure your e-bike is powered off and the battery is disconnected before inspecting or working on wiring and components, unless a specific test requires power.

Step 1: Let It Cool Completely

Before you even think about diagnostics, allow the motor and controller (and battery, if it also feels hot) to cool down completely to ambient temperature. This might take 30 minutes to an hour or more.

Why? Components behave differently when hot. Trying to diagnose a heat-related issue on a cool motor might not reveal the problem. Conversely, poking around hot components is risky. Moreover, sometimes, the stuttering is purely a temporary thermal protection response that resolves itself once temperatures normalize.

Step 2: Inspect and Test Hall Sensors and Their Wiring

Given that Hall sensor issues are a prime suspect for heat-induced stuttering:

-

Visual Inspection (Motor Internals - Advanced Users/Professionals): If you are comfortable and experienced with e-bike motor disassembly (and it doesn't void your warranty), you could open the motor hub. Look for any signs of burnt components on the Hall sensor PCB, discolored wires, or melted insulation near the sensors. This is an advanced step; proceed with extreme caution or leave it to a professional.

-

Wiring and Connectors (Motor to Controller): This is more accessible. Carefully trace the Hall sensor cable (usually a smaller cable with 5-6 wires) from the motor to the controller.

Inspect its entire length for any pinches, abrasions, or heat damage;Disconnect and inspect the connector at both ends (if possible). Look for corrosion (greenish or whitish deposits), bent or pushed-in pins, or melted plastic within the connector housing. Clean with contact cleaner if necessary and ensure a snug fit upon reconnection. -

Professional Testing: A technician can use a multimeter or an oscilloscope to verify the Hall sensor signals while spinning the motor, confirming if they are switching correctly and consistently.

Step 3: Scrutinize Phase Wire Integrity

The thick phase wires are crucial for power delivery:

-

Visual Inspection: Carefully examine the three phase wires running from the motor to the controller. Look for any signs of insulation damage (melting, cracking, abrasions), especially near the motor exit point and at the connectors.

-

Connectors: Check the phase wire connectors (often bullet connectors or a larger multi-pin connector). Ensure they are tight, clean, and show no signs of overheating (discoloration, melted plastic). Loose phase wire connections are a common cause of stuttering and can generate significant heat themselves.

-

Professional Checks: A technician might measure phase-to-phase voltages or resistances to detect irregularities indicative of wiring or internal motor winding issues.

Step 4: Evaluate the Controller's Behavior

The controller might be triggering the stutter:

-

Power Cycle: After the system has cooled, simply turning the e-bike off and then on again can sometimes reset a controller that was stuck in a thermal protection lockout.

-

Observe Heat: Try to (carefully) determine if the controller unit itself is becoming excessively hot during operation, particularly when the stuttering occurs. A very hot controller might be undersized for your riding demands or failing.

-

Professional Diagnosis/Replacement: If the stuttering consistently appears when the system is hot and other checks reveal no issues, the controller itself might be faulty or frequently entering thermal protection. A professional can diagnose this. Consider an upgrade to a higher-rated or programmable controller if you frequently push your e-bike hard, but ensure compatibility.

Step 5: Check Battery Health and All Connections

A struggling battery can manifest as stuttering under load and heat:

-

Battery Temperature: Ensure the battery itself isn't overheating. While some warmth is normal during discharge, an excessively hot battery is a concern.

-

Main Terminals: Power off and disconnect the battery. Inspect the main power terminals on the battery and the bike's cradle/connector. They should be clean, tight, and free of corrosion or arcing marks. Loose battery connections can cause power interruptions (stuttering) and generate heat.

-

Recognize Failing Battery Signs: A battery nearing the end of its life will exhibit more pronounced voltage sag, especially when hot. If the stuttering is accompanied by significantly reduced range or the battery not holding a charge as well as it used to, it might be time for a replacement.

Step 6: Verify Sensor and Magnet Alignment

This applies mainly to external speed sensors but can also be a factor if Hall sensors inside the motor have shifted due to severe stress.

-

External Speed Sensors: If your e-bike uses an external speed sensor (often a magnet on a spoke and a sensor on the frame/fork), ensure the magnet is securely mounted and passes the sensor at the correct distance (consult your e-bike manual).

-

Internal Alignment: Internal Hall sensor alignment is typically factory-set. If you suspect this, it's definitely a job for an experienced technician, as it often requires motor disassembly and precise positioning.

Proactive Measures for a Cool-Running, Stutter-Free Motor

Preventing your e-bike motor from stuttering after overheating largely comes down to managing heat and reducing stress on the system.

Ride Smart, Ride Cooler

To ride smarter and keep your e-bike motor cooler, use the lowest practical pedal assist level, as high assist generates more heat. Use the throttle sparingly, especially on starts and steep hills. Pace yourself on long climbs, taking breaks if needed to allow the system to cool, and always respect your e-bike's weight capacity to avoid overloading the motor.

Ensure Component Compatibility and Quality

Make sure your motor, controller, and battery are appropriately rated for your riding style and the typical demands you place on them. An undersized controller for a powerful motor, for example, is a recipe for overheating; Invest in quality components from reputable brands, as they often have better thermal management and durability.

Consider Cooling Enhancements (Use with Caution)

Some riders add aftermarket heat sinks to their hub motors or controllers. Ventilated motor covers are also available for some models. But before that, ensure any modifications don't compromise weather resistance or void your warranty. Improperly installed cooling aids could even worsen things.

Regular Maintenance is Key

Keep the exterior of your motor clean. Dirt and grime can act as insulators, trapping heat;

Periodically inspect all electrical connections (battery, controller, motor) for tightness and cleanliness; Listen for any unusual noises from the motor that might indicate developing mechanical issues.

Conclusion

An e-bike motor stuttering after overheating is a clear distress signal from your ride. It’s a call to investigate the thermal stresses affecting its components. By understanding the potential causes – from struggling Hall sensors and compromised wiring to protective controller actions and battery sag – and by following a methodical troubleshooting approach, you can often pinpoint and resolve the issue. More importantly, by adopting smart riding habits and performing regular maintenance, you can significantly reduce the chances of heat-related problems, ensuring your e-bike remains a reliable and smooth companion for all your adventures.

FAQs

Why does my e-bike motor start stuttering or jerking only after it gets hot, like after a long hill?

This is typically due to components like Hall sensors in the motor becoming erratic at high temperatures, the controller entering a thermal protection mode to prevent damage, or increased electrical resistance in wires/connections when hot, leading to inconsistent power delivery.

What's the first thing I should do if my e-bike motor stutters after overheating?

The very first step is to stop riding and allow the entire system (motor, controller, battery) to cool down completely. Often, this alone can temporarily resolve the issue if it was a thermal protection response. Once cool, you can begin inspecting connections and components.

Can I prevent my e-bike motor from overheating and then stuttering?

Yes, prevention includes using lower pedal assist levels, avoiding prolonged high-load situations (like steep climbs in high gear), ensuring your e-bike components are adequately rated for your use, keeping electrical connections clean and tight, and allowing the motor to cool during very demanding rides.

💡 Explore More Here!

- Everything You Need to Know About Your Ebike Frame

- Types of E-Bike Sensors: Everything You Need to Know for an Enhanced Ride

- Top Mid-Drive eBike Conversion Kits: Your Easy Guide to Choosing the Best One

- E-Bike Battery Maintenance: What Every Rider Needs to Know

- EBike Noise: Identifying Sources and Solution