How Mid-Drive Motors Use E-bike Gears for Cooler, More Efficient Riding

While an e-bike's power ratings are important, they don't tell the whole story. The true advantage of a mid-drive motor lies in its powerful synergy with your bicycle's gears—a partnership that explains their impressive climbing power, smooth speed, and excellent battery range.

Unlike a hub motor, which often operates outside its ideal conditions, a mid-drive motor leverages your bike's gears to stay in its most efficient "sweet spot." This isn't just a minor feature; it's the key to preventing motor overheating and delivering a more powerful and intuitive ride. Understanding this concept will fundamentally change how you view e-bike performance.

Understanding the Mid-Drive Advantage: Location is Everything

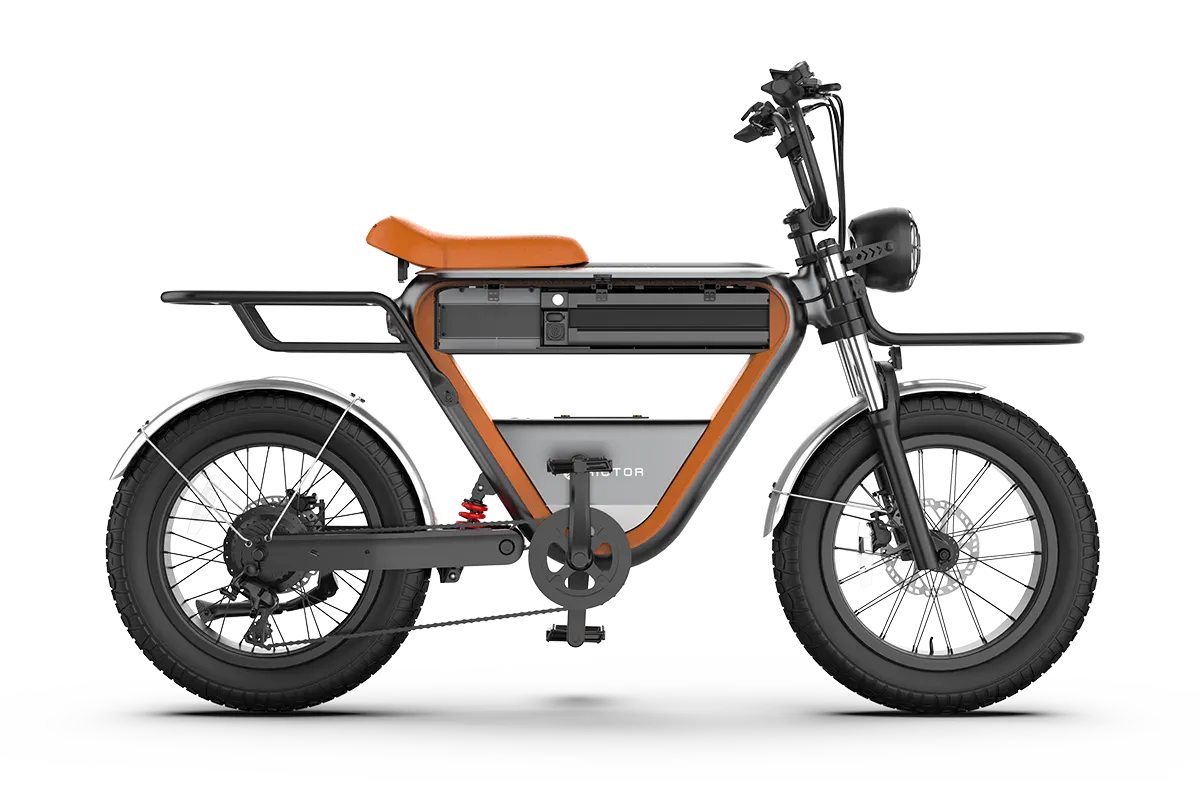

To understand the mid-drive advantage, start with its location. Unlike hub motors in the wheel, a mid-drive motor is mounted at the bike's cranks. This central placement is key.

The motor applies power directly to the drivetrain (the chain and gears), the same system your legs use. This allows it to leverage the bike's existing gears, acting like a car's engine with a transmission. You can shift to a low gear for climbing or a high gear for speed.

A hub motor's speed, in contrast, is locked to the wheel's speed, giving it no such mechanical advantage. This is why leading brands like Bosch and Shimano focus on mid-drive technology—it unlocks a higher level of performance and efficiency. While the central motor placement also improves the bike's balance, its primary advantage is this intelligent use of the gears.

The Secret to E-Bike Motor Efficiency: The Optimal RPM Range

To truly grasp why gears are so vital for a mid-drive motor, we need to talk about a core concept in electric motor performance: the optimal RPM (Revolutions Per Minute) range, often referred to as the "sweet spot." Every electric motor, from the one in your blender to the one on your e-bike, has an efficiency curve. This curve illustrates that the motor is not equally efficient at all speeds. There is a specific range of rotational speeds where the motor converts the maximum amount of electrical energy from the battery into mechanical force, wasting the least amount of energy as heat.

Operating a motor within this sweet spot is the ultimate goal for any e-bike designer and should be for any rider. When the motor is happy and efficient, you get more power, more range from your battery, and, critically, the motor generates less waste heat.

What Happens Outside the "Sweet Spot"?

A motor's performance, efficiency, and temperature can change dramatically when it's forced to operate outside this optimal RPM range. There are two primary scenarios where this happens:

Lugging (Spinning Too Slowly)

This is the most common and detrimental situation. Lugging occurs when the motor is under a heavy load but is unable to spin at a sufficient speed. A classic example is trying to start from a standstill on a very steep hill in a high gear. To generate the immense torque required to get you moving, the motor's controller has to pump a massive amount of electrical current (amps) into the windings. Because the motor isn't spinning fast enough, much of this electrical energy isn't effectively converted into rotational force.

Instead, it's dissipated as waste heat due to the motor's internal electrical resistance—a phenomenon known as I²R loss. The result is a motor that gets very hot, very quickly, while draining your battery at an alarming rate and providing sluggish performance. This is the primary cause of e-bike motor overheating.

Spinning Out (Spinning Too Fast)

This scenario is less damaging but still inefficient. If the motor is spinning at an excessively high RPM with very little load—for instance, pedaling furiously downhill in your lowest gear—it moves past its peak efficiency point. While it's not generating damaging levels of heat, it's also not producing its best power and is operating outside its ideal parameters.

The key takeaway is that an efficient ride is one where the motor is allowed to spin at a comfortable and consistent cadence, within its optimal RPM range, regardless of how fast the bike is actually traveling over the ground. This is a puzzle that a hub motor cannot solve on its own, but one that a mid-drive motor, with the help of gears, solves brilliantly.

Your Bike's Gears: The Mid-Drive Motor's Best Friend

This brings us to the core of our discussion: how your bike’s gears serve as the perfect tool to keep your mid-drive motor operating in its high-efficiency sweet spot. By shifting gears, you are changing the ratio between how fast the motor (and your pedals) are spinning and how fast the rear wheel is turning. This allows you to completely decouple the motor's speed from the bike's ground speed, giving you precise control over the motor's performance.

Let’s walk through two common riding scenarios to see this synergy in action.

Scenario 1: Conquering a Steep Hill

Imagine you are approaching a steep, challenging climb. On a bike with a hub motor, your ground speed would drop significantly. Since the hub motor's speed is tied to the wheel's speed, the motor would be forced to slow down, entering that dreaded "lugging" state. It would draw huge amounts of current, struggle to produce enough torque, and get progressively hotter.

Now, let's replay that scene on a mid-drive e-bike:

-

Your Action: As you approach the hill and your pedaling becomes difficult, you do what any cyclist would do: you shift into a lower gear (a larger cog on the rear cassette).

-

The Mechanical Effect: Shifting to an easier gear allows you to maintain a high, comfortable pedaling cadence even though your forward speed has decreased. You are spinning your legs faster to make the wheel turn slower.

- The Motor's Reaction: Because the mid-drive motor is connected to your pedals, it also gets to spin faster! Even though the bike is moving slowly up the hill, the motor is happily whirring away within its optimal, high-efficiency RPM range. In this range, it produces its maximum torque with minimal effort and heat generation. Furthermore, the gear you've selected acts as a torque multiplier.

- The high torque produced by the efficient motor is then amplified by the low gearing, delivering incredible climbing power to the rear wheel. The result is that you ascend the hill with what feels like superhuman strength, while the motor remains cool, calm, and collected, sipping energy from the battery efficiently instead of gulping it down.

Scenario 2: Cruising at High Speed on a Flat Road

Now let’s consider the opposite situation: you’re on a long, flat stretch of road and want to reach your top cruising speed.

-

Your Action: As you accelerate, you systematically shift into higher gears (smaller cogs on the rear cassette).

-

The Mechanical Effect: This allows you to keep your pedaling cadence at a comfortable and powerful rhythm (e.g., 80-90 RPM) while the bike's ground speed increases significantly.

-

The Motor's Reaction: Once again, the motor mirrors your cadence. It remains in its optimal RPM sweet spot, efficiently providing the power you need to maintain a high speed. It's not "spinning out" or straining; it's simply operating where it was designed to perform best. A hub motor, in this situation, might be approaching the upper limit of its Kv rating (its maximum RPM per volt), where its torque output begins to drop off. A mid-drive, however, can continue to provide effective and efficient assistance across a much broader range of road speeds, all thanks to the rider’s ability to select the appropriate gear.

By continuously using the gears to manage the load on the motor, you are essentially acting as the bike's "smart transmission." You are ensuring the motor never has to lug inefficiently on a climb or spin uselessly on a flat. This constant optimization is what leads directly to a cooler motor, a longer-lasting battery, and a more responsive and powerful ride across all types of terrain.

A Note on Drivetrain Maintenance for Mid-Drive E-Bikes

This powerful system does come with one important consideration: drivetrain wear. Because the mid-drive motor applies its considerable force directly to the chain, cassette, and chainring, these components are placed under significantly more stress than on a non-electric bike or one with a hub motor. This is not a flaw, but rather a predictable consequence of its powerful design. To ensure the longevity and smooth operation of your mid-drive e-bike, proper maintenance is key.

-

Use E-Bike Specific Components: Many manufacturers now produce chains and cassettes specifically designed to handle the higher torque of mid-drive systems. These are often made from stronger materials and are a worthwhile investment.

-

Shift Smoothly: Avoid shifting gears while the motor is under maximum load. Ease off the pedals for a split second as you shift. Many modern mid-drive systems, like those from Bosch and Shimano, incorporate "shift detection" technology that momentarily reduces the motor's power as you shift to protect the drivetrain and ensure a smoother gear change.

- Keep it Clean and Lubricated: A clean drivetrain is a happy and efficient drivetrain. Regularly cleaning and lubricating your chain will dramatically reduce wear and tear on all components and improve performance.

-

Regular Inspections: Periodically check your chain for "stretch" (wear) using a chain checker tool. Replacing a worn chain is far cheaper than replacing a worn chain, cassette, and chainring all at once.

By following these simple maintenance steps, you can enjoy the incredible performance benefits of a mid-drive motor for many thousands of miles.

Couclusion

In e-bike technology, the true measure of a great system is its intelligence and efficiency, not just raw power. Mid-drive motors are smarter because they seamlessly integrate with your bike's geared drivetrain.

By using your gears, you keep the motor in its optimal RPM range, turning it into a versatile powerhouse that can be a high-torque hill-crusher one moment and a high-speed cruiser the next, all while staying cool and efficient. This results in tangible benefits: longer battery range, greater confidence on any terrain, a longer motor lifespan, and an intuitive ride.

Remember, your shifters are the controls to this sophisticated system. Using them wisely unlocks the full, incredible potential of your ride.

FAQs

Why do mid-drive e-bikes feel so much more powerful when climbing steep hills?

It's all about the gears. By shifting to a low gear on a hill, you allow the mid-drive motor to spin quickly and stay in its most efficient, high-torque RPM range. The bike's gears then act as a torque multiplier, delivering massive power to the rear wheel. A hub motor, by contrast, is forced to slow down with the wheel, causing it to struggle and overheat.

Do mid-drive motors give you better battery range?

Yes, generally they do. Because using the gears keeps the motor operating in its most efficient "sweet spot," less electrical energy from the battery is wasted as heat. This superior efficiency means more of the battery's power is converted into forward motion, resulting in a longer overall range compared to a less efficient motor.

Is it necessary to shift gears all the time on a mid-drive e-bike?

Yes, to get the best performance, you should treat it like a regular bicycle. Shifting to the appropriate gear for the terrain (lower gears for hills and starting, higher gears for speed on flats) is crucial. This not only gives you a better ride feel but also maximizes the motor's efficiency, extends your battery range, and prevents the motor from overheating, which prolongs its life.

💡 Explore More Here!

- Everything You Need to Know About Your Ebike Frame

- Types of E-Bike Sensors: Everything You Need to Know for an Enhanced Ride

- Top Mid-Drive eBike Conversion Kits: Your Easy Guide to Choosing the Best One

- E-Bike Battery Maintenance: What Every Rider Needs to Know

- EBike Noise: Identifying Sources and Solution